Common Rail Diesel Operating Engine with Manual Transmission Training Bench

About

Feature

Technical Parameter

Basic Configuration

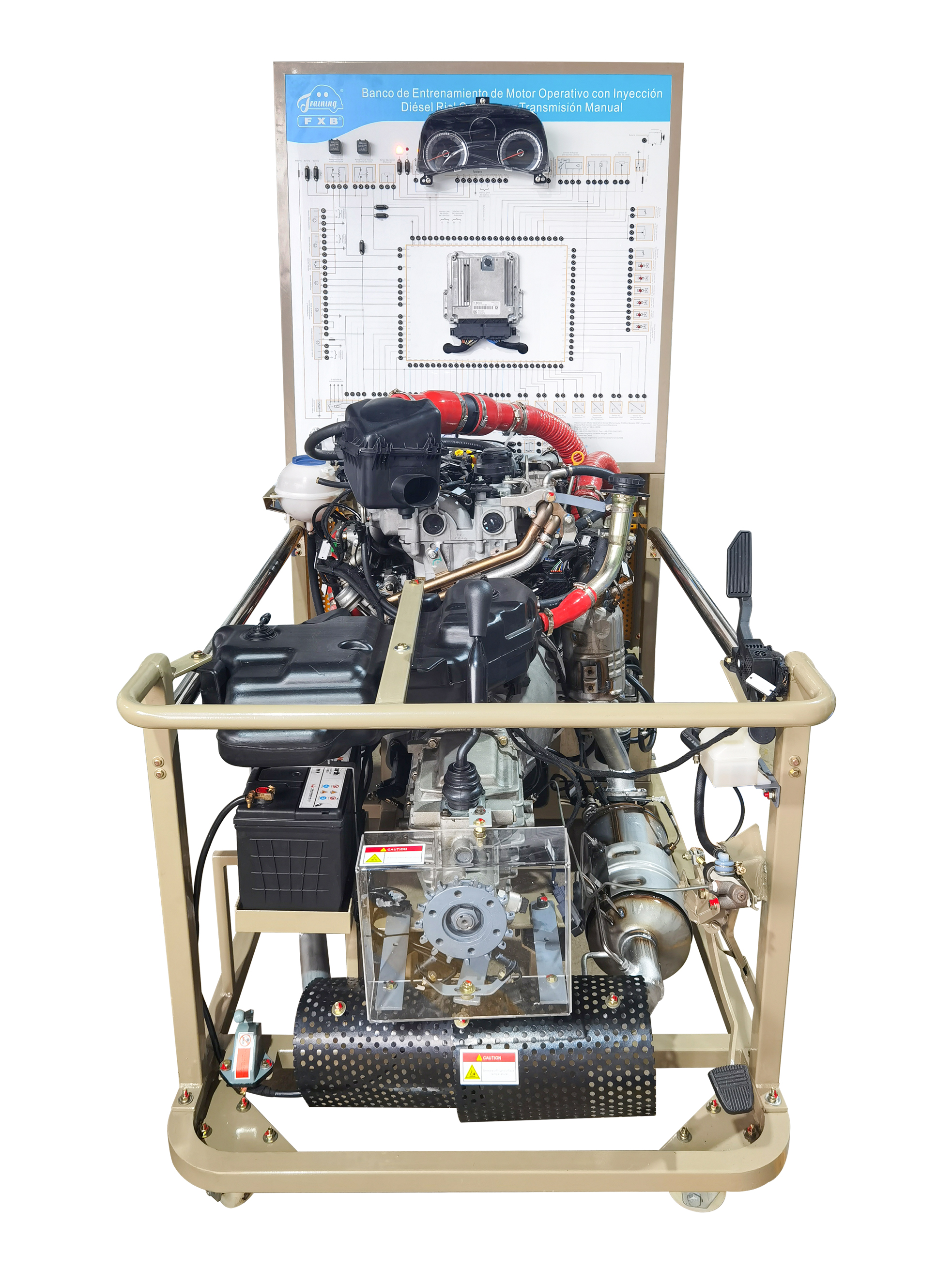

Common Rail Diesel Operating Engine with Manual Transmission Training Bench

Isuzu brand 2.5T JX4D common rail diesel engine trainer,4 cylinders,4 stroke,2,500cc,direct injection,turbocharger,common rail 5-speed mechanical transmission and reverse,model 2022.Mounted on a robust metal structure,with resistant wheels and control panel with SCR. New engine,diesel intermal combustion,4 cylinders in line,with complete exhaust system,catalytic converter,charging and starting system, engine cooling system,battery,air supply system,electronic fuel injection system type common rail,throttle control,control panel with RPM. fuel level,engine temp,electrical load,check engine signal,key ignition switch,two keys will be issued.

FXB-A18006 board for measurement of sensors and actuators in real time,with installed ECU and wiring diagram with test connectors, banana type,for signal measurement.

Electronic fault insertion system using a wireless tablet PC device,to carry out diagnostic practices by teachers and students. OBDII diagnostic connector,5 gallon fuel tank,with key cap,and fuel level signal sender unit to display on the control panel.

Didactic manual for student and teacher in English,Manual of technical specifications of the manufacturer's injection system and user and maintenance manual in English.

Technical induction for use and operation of the trainer.

Car model:Isuzu 2.5T Engine model JX4D,Displacement 2.5T,Inline four cylinder four stroke,Direct injection,16 valves,High pressure common rail diesel engine, DOHC Maximum power 103kW.Maximum torque 315N-m,with 5 speed plus R manual transmission,model 2022, demonstrable by scanner.

1.New electronically-controlled high-pressure common rail diesel engine with manual transmission to illustrate the structure and working process.

2.It comes with a training panel which made of 4mm thick aluminum-plastic plate.Never fade color circuit diagram and working principal diagram are painted on the panel whose surface coating with varnish.The trainees can learn and analyze the working principle of engine control system by referencing the diagram and the real components.

3.Detection terminals are installed on the training panel.Operators can use multimeter and oscilloscope to detect the resistance,voltage and waveform signals from various sensors,executors and electrical signals in ECU pins.

4.It's installed with dashboard to illustrate changes of parameters including the engine speed,coolant temperature,fuel level,oil pressure indicator,charging indicator and fault indicators.

5.It's installed with OBD ll diagnostic socket,which can connect to diagnostic tool to read fault codes,clears fault codes and reads data stream from the engine electrical control system.

6.An accelerator pedal is installed to accelerate and deceleration,clutch pedal and gear shift lever are installed for shifting gears.

7.The engine is equipped with SCR (Selective Catalytic Reduction)system to reduce nitrogen oxides NOx emissions,urea is applied. 8.A master power switch,coolant tank protector and transmission output shaft protector are installed for safety consideration.

9.The base frame of training bench is made in steel and the surface is paint-coated.Lockable casters are installed to ensure movable in classroom.

10.The language for the panel is Spanish.

11.The equipment is provided with teacher manual,students manual,and maintenance manual.It's helpful for training and learning.English manual of technical specifications of the common rail system.

12.Equipped with wireless intelligent fault setting and appraisal system,teachers set faults by tablet PC then ask students to detect and find the fault.It's helpful for teachers to know about students' learning status,also can improve students' skills in troubleshooting.

13. Compliance with ISO and CE standards

Detection and control panel (with various detection terminals,color circuit diagram),Ignition switch,ECU,Dashboard,OBDII diagnostic socket,Turbo pressure meter,Diesel engine assembly,Air flow sensor,Oxygen sensor,Crankcase pressure sensor,Turbocharging

temperature sensor,Turbocharging pressure sensor,Fuel temperature sensor,Throttle position sensor,Accelerator pedal position sensor,

Camshaft position sensor,Crankshaft rotational speed sensor,Coolant temperature sensor,Temperature sensors,Fuel rail pressure sensor,

Turbocharging pressure meter,Urea tank,Urea injector,Urea level /temperature sensor and heater,NOx Sensor,

Manual transmission assembly.Clutch pedal,Gear shift lever,5 US galón (19L)Fuel tank,High pressure fuel pump,Accelerator pedal,Inlet and exhaust pipes (including protection covers),Coolant tank (including protection cover),Cooling fan,Battery,Relay,Fuse,Master power switch,Tablet PC included,Wireless intelligent fault-setting and appraisal system,Movable framework with lockable casters.

Isuzu brand 2.5T JX4D common rail diesel engine trainer,4 cylinders,4 stroke,2,500cc,direct injection,turbocharger,common rail 5-speed mechanical transmission and reverse,model 2022.Mounted on a robust metal structure,with resistant wheels and control panel with SCR. New engine,diesel intermal combustion,4 cylinders in line,with complete exhaust system,catalytic converter,charging and starting system, engine cooling system,battery,air supply system,electronic fuel injection system type common rail,throttle control,control panel with RPM. fuel level,engine temp,electrical load,check engine signal,key ignition switch,two keys will be issued.

FXB-A18006 board for measurement of sensors and actuators in real time,with installed ECU and wiring diagram with test connectors, banana type,for signal measurement.

Electronic fault insertion system using a wireless tablet PC device,to carry out diagnostic practices by teachers and students. OBDII diagnostic connector,5 gallon fuel tank,with key cap,and fuel level signal sender unit to display on the control panel.

Didactic manual for student and teacher in English,Manual of technical specifications of the manufacturer's injection system and user and maintenance manual in English.

Technical induction for use and operation of the trainer.

Car model:Isuzu 2.5T Engine model JX4D,Displacement 2.5T,Inline four cylinder four stroke,Direct injection,16 valves,High pressure common rail diesel engine, DOHC Maximum power 103kW.Maximum torque 315N-m,with 5 speed plus R manual transmission,model 2022, demonstrable by scanner.

1.New electronically-controlled high-pressure common rail diesel engine with manual transmission to illustrate the structure and working process.

2.It comes with a training panel which made of 4mm thick aluminum-plastic plate.Never fade color circuit diagram and working principal diagram are painted on the panel whose surface coating with varnish.The trainees can learn and analyze the working principle of engine control system by referencing the diagram and the real components.

3.Detection terminals are installed on the training panel.Operators can use multimeter and oscilloscope to detect the resistance,voltage and waveform signals from various sensors,executors and electrical signals in ECU pins.

4.It's installed with dashboard to illustrate changes of parameters including the engine speed,coolant temperature,fuel level,oil pressure indicator,charging indicator and fault indicators.

5.It's installed with OBD ll diagnostic socket,which can connect to diagnostic tool to read fault codes,clears fault codes and reads data stream from the engine electrical control system.

6.An accelerator pedal is installed to accelerate and deceleration,clutch pedal and gear shift lever are installed for shifting gears.

7.The engine is equipped with SCR (Selective Catalytic Reduction)system to reduce nitrogen oxides NOx emissions,urea is applied. 8.A master power switch,coolant tank protector and transmission output shaft protector are installed for safety consideration.

9.The base frame of training bench is made in steel and the surface is paint-coated.Lockable casters are installed to ensure movable in classroom.

10.The language for the panel is Spanish.

11.The equipment is provided with teacher manual,students manual,and maintenance manual.It's helpful for training and learning.English manual of technical specifications of the common rail system.

12.Equipped with wireless intelligent fault setting and appraisal system,teachers set faults by tablet PC then ask students to detect and find the fault.It's helpful for teachers to know about students' learning status,also can improve students' skills in troubleshooting.

13. Compliance with ISO and CE standards

Detection and control panel (with various detection terminals,color circuit diagram),Ignition switch,ECU,Dashboard,OBDII diagnostic socket,Turbo pressure meter,Diesel engine assembly,Air flow sensor,Oxygen sensor,Crankcase pressure sensor,Turbocharging

temperature sensor,Turbocharging pressure sensor,Fuel temperature sensor,Throttle position sensor,Accelerator pedal position sensor,

Camshaft position sensor,Crankshaft rotational speed sensor,Coolant temperature sensor,Temperature sensors,Fuel rail pressure sensor,

Turbocharging pressure meter,Urea tank,Urea injector,Urea level /temperature sensor and heater,NOx Sensor,

Manual transmission assembly.Clutch pedal,Gear shift lever,5 US galón (19L)Fuel tank,High pressure fuel pump,Accelerator pedal,Inlet and exhaust pipes (including protection covers),Coolant tank (including protection cover),Cooling fan,Battery,Relay,Fuse,Master power switch,Tablet PC included,Wireless intelligent fault-setting and appraisal system,Movable framework with lockable casters.