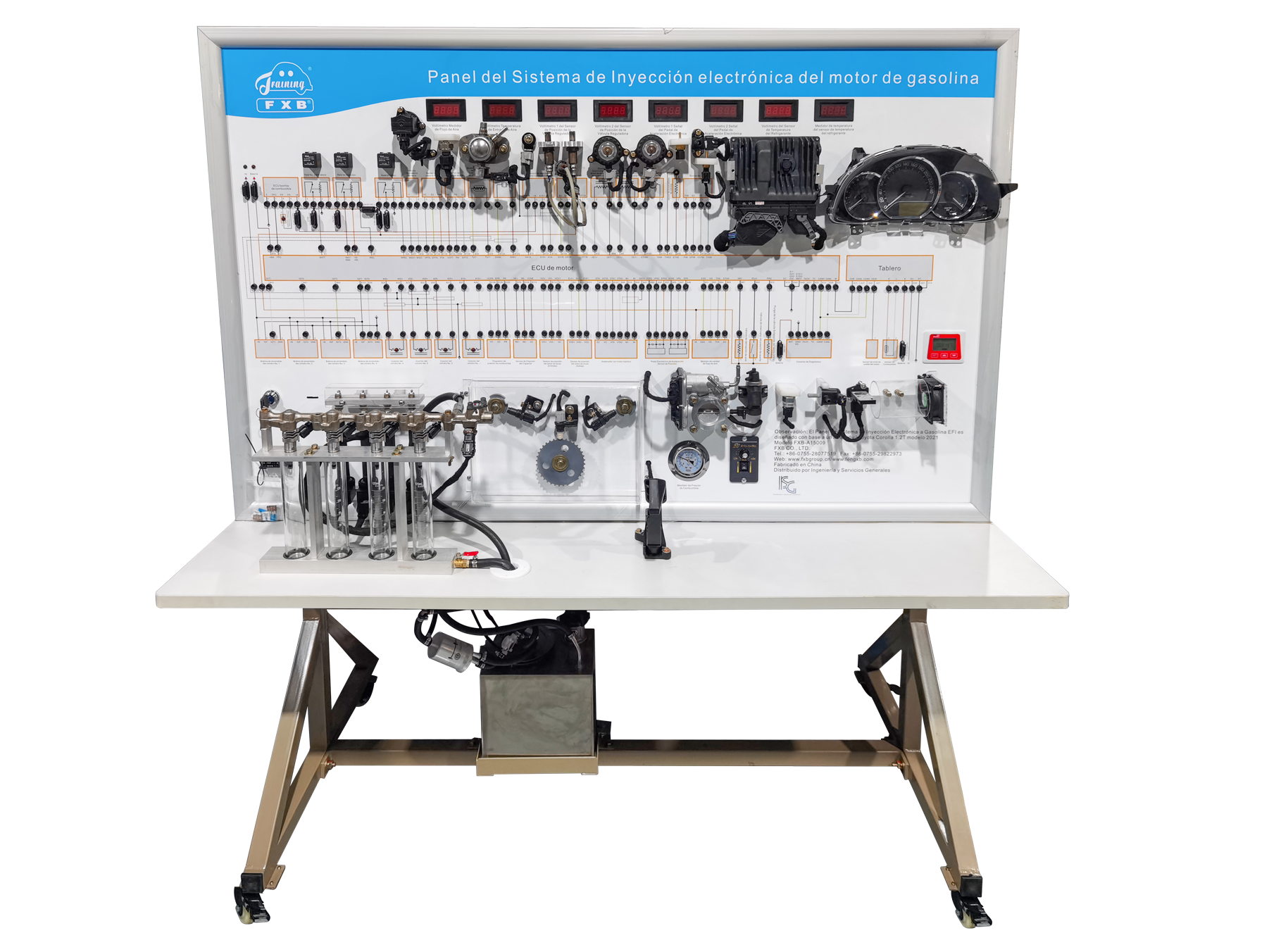

EFI Gasoline Engine Electronic Control System Training Panel

About

Feature

Technical Parameter

Basic Configuration

Electronic multipoint gasoline injection panel,based on the Toyota Corolla 1.2T car,model 2022,demonstrable by scanner,for the study of injection at different loads,temperatures and different speeds,MAF sensor and oxygen sensor function,measurement of injection time with oscilloscope and tachymeter.Injector opening ratio-injected volume,temperature-injection volume ratio.Measurement of injector actuation signals,sensor valve switch,oscilloscope study,valve position,etc.

Panel,with metal frame with high-resistance rollers and lockable casters.With control panel,electrical diagram on the panel with labels in Spanish,ECU control unit with CAN BUS,ignition switch with key.(2 keys),OBDII diagnostic socket,power supply 220VAC,60 Hz., Electronic gasoline injection multipoint,with real and new components,with real effect of electronic gasoline injection.Dashboard,fuel tank, fuel pump,pump relay,spark plugs,fuel injectors,injector nozzle,crankshaft position sensor and signal wheel,air supply fan,fuel flow indicator,oxygen sensor,engine speed adjustment,intelligent wireless fault insertion system with installed software,wireless tablet,with operation indicator device.Dashboard.Electrical diagram in panel with measurement points and data collection terminals in the electronic control unit ECU to measure sensor and actuator of the panel.Dash Mounted ECU.Ignition Switch,Two Keys Included,OBDII Diagnostic Connector

Includes gasoline internal combustion engine sensors,pressure gauges to measure fuel pressure and flow,Engine temperature sensor simulator and temperature data display device,banana plug terminals corresponding to ECU,speed signal generator,ECU can be combined to CAN-Bus.

Includes measurement terminals for each sensor and actuator.Includes fuel supply circuit,air supply circuit,ignition circuit,RPM sensor, engine camshaft position sensor,engine crankshaft rpm indicator,coolant temperature sensor,lambda probe,failure lamp on the board. Real effect of electronic fuel injection.

Experiments can be performed injection time,fuel cut during deceleration phase,maximum speed limiter,fault light on the dashboard.

Includes tablet and fault insertion software installed on the tablet with Wi-Fi communication between panel and tablet PC.Panel operating voltage:12VDC,supplied by the internal power supply,with overvoltage and short circuit protection.Protection cover.Technical induction for operation and maintenance,technical manuals with technical specifications of the manufacturer's EFI system are included.User and maintenance manual English.Didactic manual.

1.Real and operable engine electronic control system.The crankshaft signal wheel is driven by the electric motor,so the crankshaft position sensor can sense the signal and send to ECU.Then the spark plug ignition,fuel pump operation and fuel injection.

2.It comes with a training panel which made of 4mm thick aluminum-plastic plate.Never fade color circuit diagram are painted on the board whose surface coating with varnish.The trainees can learn and analyze the working principle of the control system by referencing the diagram and the real object.

3.Detection terminals are installed on the training panel.Operators can detect resistance,voltage,waveform signals of various sensors / actuators /engine ECU by multimeter and oscilloscope.

4.The training panel is installed with diagnostic socket,which can connect to automobile decoder to read fault codes and clears fault codes from the engine electrical control system.

5.The base frame of training bench is made in steel and the surface is paint-coated.Lockable casters are installed to ensure movable in classroom.

6.It connects to 220V AC voltage which changes to 12 V DC voltage through the internal circuit.The 12V DC voltage protects the training panel against short circuit.

7.The language for the panel is Spanish.

8.The equipment is provided with teacher manual,students manual,and maintenance manual.It's helpful for training and leaming.English manual of technical specifications of the EFI system.

9.Equipped with wireless intelligent fault-setting and appraisal system,teachers set faults by tablet PC included,then ask students to detect and find the fault.It's helpful for teachers to know about students' learning status,also can improve students' skills in troubleshooting.

10.Compliance with ISO and CE standards.

11.The training panel contains the Toyota CAN BUS net work communication function.Some related engine sensors are included,like MAF sensor oxygen sensor.

12.Completed relative fuel supply,air supply,ignition system:

1)Fuel supply circuit

Through adding one fuel volume meter on the rail to get four injectors injected fuel volume stainless steel fuel tank with never color fading feature.With electrical fuel pump

2)Air supply circuit

Through adding one small fan before the glass pipe between throttle body and air flow meter to simulate inlet air flow and through this to judge if the air is in or not from fan rotate or not rotate.Engine temperature simulator.Accelerator pedal potentiometer

3)lgnition system

4 sparking plugs and 4 ignition coils.All the related diagnostic can be done through related ignition electricity spare parts

4)Engine related spare parts

Ignition key (2 keys)with immobilizer, OBDII connector,CAN BUS transmission

5)Additional function with adding parts

One speed adjusting motor to control crankshaft position sensor to simulate the maximum speed limiter,RPM can be clearly demonstrated by the dashboard.Throttle valve position sensor signal voltage.Pressure gauge for measuring fuel pressure.Device to measure fuel flow Speed signal generator device

Cover for panel included

Panel,with metal frame with high-resistance rollers and lockable casters.With control panel,electrical diagram on the panel with labels in Spanish,ECU control unit with CAN BUS,ignition switch with key.(2 keys),OBDII diagnostic socket,power supply 220VAC,60 Hz., Electronic gasoline injection multipoint,with real and new components,with real effect of electronic gasoline injection.Dashboard,fuel tank, fuel pump,pump relay,spark plugs,fuel injectors,injector nozzle,crankshaft position sensor and signal wheel,air supply fan,fuel flow indicator,oxygen sensor,engine speed adjustment,intelligent wireless fault insertion system with installed software,wireless tablet,with operation indicator device.Dashboard.Electrical diagram in panel with measurement points and data collection terminals in the electronic control unit ECU to measure sensor and actuator of the panel.Dash Mounted ECU.Ignition Switch,Two Keys Included,OBDII Diagnostic Connector

Includes gasoline internal combustion engine sensors,pressure gauges to measure fuel pressure and flow,Engine temperature sensor simulator and temperature data display device,banana plug terminals corresponding to ECU,speed signal generator,ECU can be combined to CAN-Bus.

Includes measurement terminals for each sensor and actuator.Includes fuel supply circuit,air supply circuit,ignition circuit,RPM sensor, engine camshaft position sensor,engine crankshaft rpm indicator,coolant temperature sensor,lambda probe,failure lamp on the board. Real effect of electronic fuel injection.

Experiments can be performed injection time,fuel cut during deceleration phase,maximum speed limiter,fault light on the dashboard.

Includes tablet and fault insertion software installed on the tablet with Wi-Fi communication between panel and tablet PC.Panel operating voltage:12VDC,supplied by the internal power supply,with overvoltage and short circuit protection.Protection cover.Technical induction for operation and maintenance,technical manuals with technical specifications of the manufacturer's EFI system are included.User and maintenance manual English.Didactic manual.

1.Real and operable engine electronic control system.The crankshaft signal wheel is driven by the electric motor,so the crankshaft position sensor can sense the signal and send to ECU.Then the spark plug ignition,fuel pump operation and fuel injection.

2.It comes with a training panel which made of 4mm thick aluminum-plastic plate.Never fade color circuit diagram are painted on the board whose surface coating with varnish.The trainees can learn and analyze the working principle of the control system by referencing the diagram and the real object.

3.Detection terminals are installed on the training panel.Operators can detect resistance,voltage,waveform signals of various sensors / actuators /engine ECU by multimeter and oscilloscope.

4.The training panel is installed with diagnostic socket,which can connect to automobile decoder to read fault codes and clears fault codes from the engine electrical control system.

5.The base frame of training bench is made in steel and the surface is paint-coated.Lockable casters are installed to ensure movable in classroom.

6.It connects to 220V AC voltage which changes to 12 V DC voltage through the internal circuit.The 12V DC voltage protects the training panel against short circuit.

7.The language for the panel is Spanish.

8.The equipment is provided with teacher manual,students manual,and maintenance manual.It's helpful for training and leaming.English manual of technical specifications of the EFI system.

9.Equipped with wireless intelligent fault-setting and appraisal system,teachers set faults by tablet PC included,then ask students to detect and find the fault.It's helpful for teachers to know about students' learning status,also can improve students' skills in troubleshooting.

10.Compliance with ISO and CE standards.

11.The training panel contains the Toyota CAN BUS net work communication function.Some related engine sensors are included,like MAF sensor oxygen sensor.

12.Completed relative fuel supply,air supply,ignition system:

1)Fuel supply circuit

Through adding one fuel volume meter on the rail to get four injectors injected fuel volume stainless steel fuel tank with never color fading feature.With electrical fuel pump

2)Air supply circuit

Through adding one small fan before the glass pipe between throttle body and air flow meter to simulate inlet air flow and through this to judge if the air is in or not from fan rotate or not rotate.Engine temperature simulator.Accelerator pedal potentiometer

3)lgnition system

4 sparking plugs and 4 ignition coils.All the related diagnostic can be done through related ignition electricity spare parts

4)Engine related spare parts

Ignition key (2 keys)with immobilizer, OBDII connector,CAN BUS transmission

5)Additional function with adding parts

One speed adjusting motor to control crankshaft position sensor to simulate the maximum speed limiter,RPM can be clearly demonstrated by the dashboard.Throttle valve position sensor signal voltage.Pressure gauge for measuring fuel pressure.Device to measure fuel flow Speed signal generator device

Cover for panel included