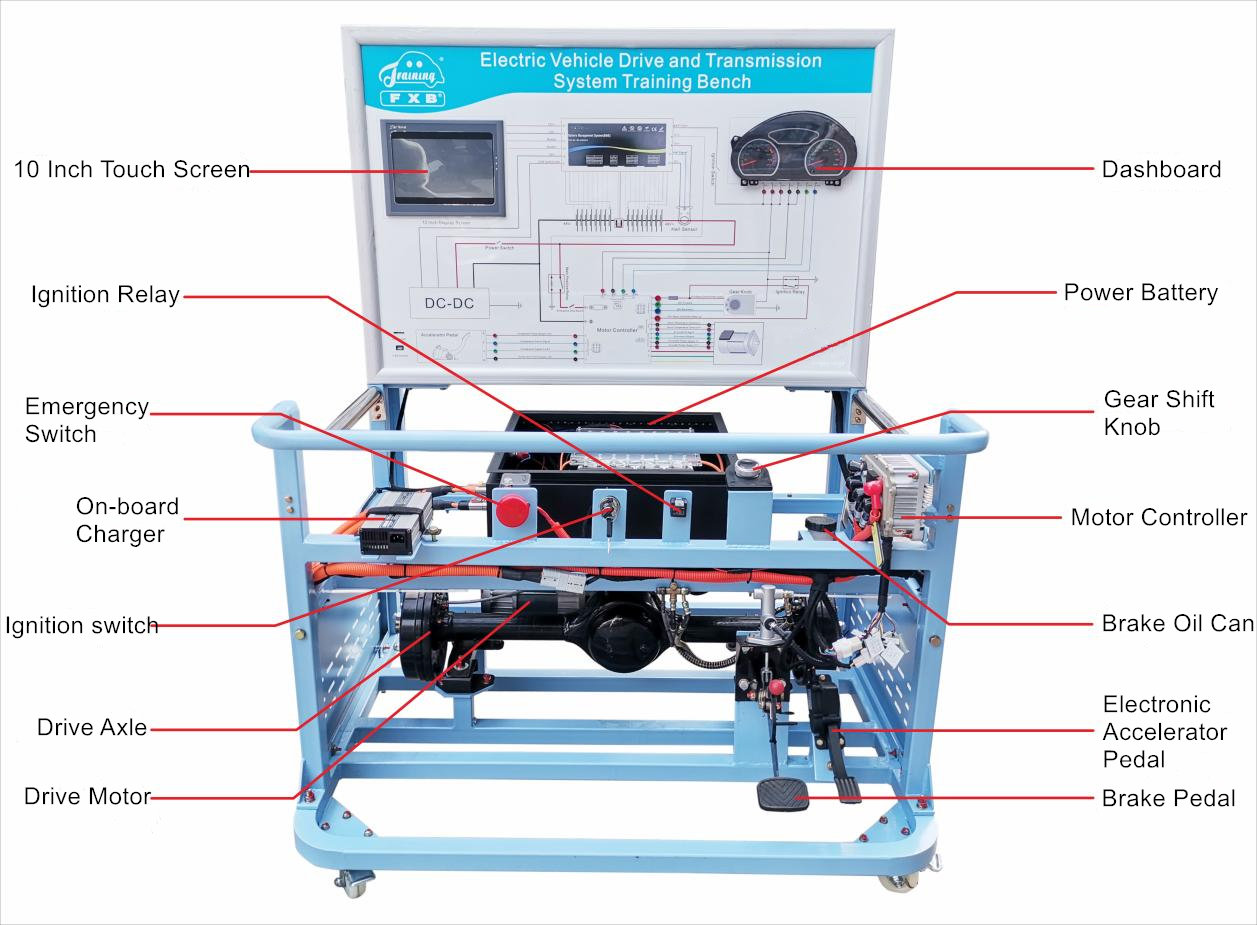

It adopts the original parts of pure electric vehicle and customized power battery, function and control mode is exactly the same as the general pure electric vehicles, which truly presents the connection control relation, installation location and operation parameters of the core components of electric vehicle drive system.

ii. Features

1. Complete electric vehicle drive and transmission system to illustrate the structure and working principle.

2. The main components are mounted on the bench, and the connection line is placed in the working place, and the circuit schematic diagram allows the students to master the working principle of the electric drive system.

3. The power battery information display screen displays the power battery voltage / current / temperature, relays status. The dashboard is installed for displaying the vehicle speed and battery level.

4. Pressing the accelerator pedal, the electric motor drives the gearbox and axle to rotate, observing the different parameters during different speed, master the control logic of electric vehicle running and the parameter changes of main components.

5. The brake pedal and hydraulic brake system is installed.

6. The power battery pack is covered with around 5mm transparent acrylic plate on the top, installed with the LED lightbulb lighting, for observing the battery structure.

7. The power battery pack is installed with a mechanical maintenance switch. Before opening the acrylic cover and checking the battery, pull out the mechanical maintenance switch at first to disconnect battery power for safety consideration. An emergency switch also installed.

8. A charger is provided to charge the power battery.

9. Lockable casters are installed to make it lockable and moveable.

10. All of the language for this equipment is English or customized language.

11. The equipment is provided with operation manual, it contains the equipment introduction, operation method, components and working principle introduction, fault-setting and troubleshooting process. It’s helpful for training and learning.

12. Equipped with wireless fault-setting and appraisal system, teachers set faults by tablet PC then ask students to detect and find the fault. It’s helpful for teachers to know about students’ learning status, also can improve students’ skills in troubleshooting.

13. Compliance with ISO and CE standards.

iii. Technical Parameters

1. Estimated dimension (mm): 1200*1000*1800 (length * width * height)

2. Input power: AC 220V±10% 50/60Hz

3. Power battery type: environmental protection type lithium iron phosphate power battery (square aluminum shell, single cell 3.2V 20AH, 16 sections in series)

Power battery pack total capacity: 51.2V 20AH

Total charge and discharge: 2000 times

Working temperature: - 20 °C ~ +40 °C

Motor controller:

Input voltage range: 40~75V DC

Rated output current: 55A

Maximum output current: 180A

Controller starting voltage: 35V DC

Communication method: CAN communication

Protection level: IP66

Insulation resistance: test insulation resistance not less than 20MΩ

Cooling method: natural air cooling

6. Drive motor:

Rated power: 2.2KW

Rated voltage: 48V

Rated current: 78A

Rated speed: 2590RPM

Rated torque: 11.1N.m

iv. Main Constituent Components

Detection and control panel (With various detection terminals and color circuit diagram), ignition switch, dashboard, power battery information display screen, lithium iron phosphate power battery with BMS, battery charger, DC-DC converter, discharging relay, charging relay, hall sensor, maintenance switch, AC controller, driving motor, motor controller, electronic accelerator pedal, gear shift lever, gearbox, brake pedal, hydraulic brake system, axle, emergency switch, wireless fault-setting program, tablet PC, movable framework (with lockable casters).

v. Equipped with Training Software

1. The software includes four modules: Overall Structure, Operation Steps, Structure Principle, Circuit Detection.

2. Introduction of four modules.

* Overall Structure:

By displaying 3D model of the equipment, students can learn the position, connection relationship and structure of components. Click components, the related introduction is displayed.

* Operation Steps:

Six operations in total. Explains the usage of equipment and safety matters in the form of animation.

* Structure Principle:

It displays the structure, and principle of each component in power battery, charger, converter, driving motor, gearbox, brake system, etc.

* Circuit Detection:

The circuit diagram is consistent with the equipment, the related data also come from and same to the equipment. The interface can be zoom in, zoom out, drag and drop for learning. And it has dynamic display of power flow.