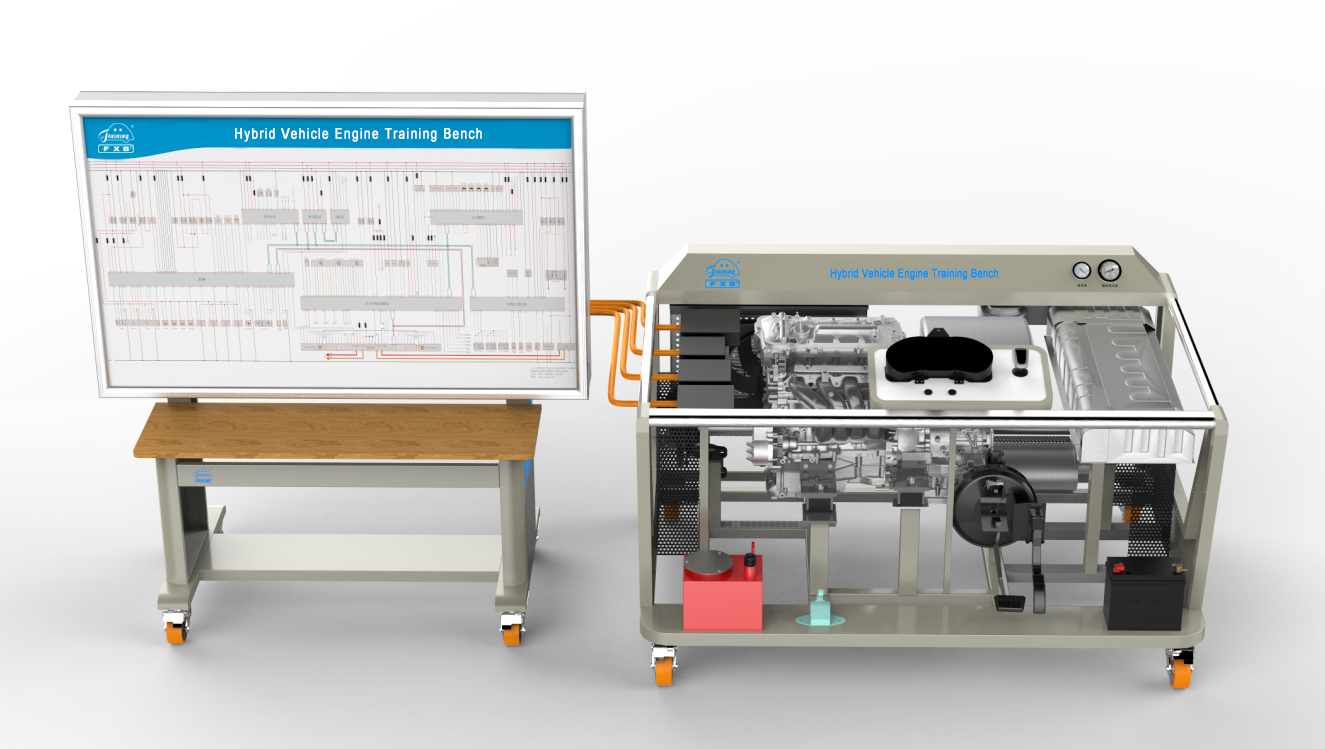

The equipment is based on the 2019 Toyota Corolla dual-engine 1.8L hybrid hybrid system (including: hybrid vehicle engine training platform, etc.) and an electronic drive axle assembly. It can carry out the practical operation of starting, accelerating and decelerating conditions for the hybrid power system and electronic transmission axle, and truly show the composition structure and working process of the hybrid power system. And it is suitable for the teaching needs of hybrid hybrid power system maintenance training in secondary and senior vocational skill schools, general education colleges and training institutions.

ii. Features

1. Select the normal operation Toyota Corolla hybrid system (including: engine, generator, electric motor, HV battery, etc.) to fully demonstrate the structure and working process of the hybrid.

2. The detection panel is made of high-grade aluminum-plastic board with a thickness of 4mm, which is corrosion-resistant, impact-resistant, pollution-resistant, fire-resistant and moisture-resistant. The surface is treated with a special process of spraying primer.

3.Through the special pair of connectors, it is connected in series with the power bench harness, and the control signal is led to the detection control box for detection and fault setting. The leading interfaces are engine control module, hybrid power control module, combination instrument control module, gateway control module, authenticate main control modules such as ECU control modules. The detection control box contains two types of mechanical faults and wireless faults, and the fault point is the main part of the control module. The teacher sets the fault, the trainees analyze and find the fault points, master the fault handling ability of the real vehicle, and the fault setting is divided into open circuit, accident and other phenomena. And there are no less than 16 wireless fault points and no less than 50 mechanical fault points.

4. There is a car instrument installed on the operation panel of the training bench, which can display the changes of parameters such as power transmission process, vehicle speed, electronic control system fault indicator and other parameters in real time. At the same time, a pointer fuel pressure gauge and a vacuum pressure gauge are also installed to display the fuel pressure and vacuum pressure in real time.

5. A detection terminal is installed on the detection panel, which can directly detect the electrical signals of the pins of the engine control module, hybrid control module, combination instrument control module, gateway control module, certification ECU control module, etc., such as resistance, voltage, current, frequency signal, etc. The detection panel is drawn with physical pictures of each control module, and the measurement signal includes the signal detection of the control module end and the wire harness end. The detection panel is connected in series with the hybrid power system through the original car connector, and the hybrid power system can operate normally when the detection panel is removed.

6. The training bench is equipped with a diagnostic socket, which can be connected to a car decoder to perform self-diagnosis functions such as reading fault codes, clearing fault codes, and reading data streams for electronic control systems such as engine, automatic transmission, hybrid power, and power supply.

7.The training bench is equipped with a throttle control device, which can facilitate the acceleration and deceleration of the engine.

8. The training bench is equipped with installation protection devices such as the main power switch, the water tank protective cover, and the half axle wheel.

9. The base of the training bench is welded by steel structure, and the surface is treated by spraying process, with self-locking caster device, flexible movement, safe, reliable and durable.

10. The main parameters of HV battery are as follows:

Each battery module consists of 6 cells, and the HV battery has a total of 168 cells (6 cells*28 modules). The rated voltage of a single cell is 1.2V, and the total voltage is 201.6V. The HV battery is cooled by a blower.

11. The main parameters of the power drive system are as follows:

Engine: not less than 90kW (1.8L naturally aspirated + electric motor)

Power type: gasoline-electric hybrid

Transmission: E-CVT

Intake form: naturally inhale

Cylinder arrangement: in-line (L type)

Number of cylinders: not less than 4

Compression ratio: not less than 13

Valve train: DOHC

12. Equipped with mechanical wireless equipment. The fault setting area is located at the lower part of the detection bench. It is designed with sliding door fault setting mechanism. The mechanical and wireless fault setting system is installed inside, and 2mm special wiring is provided for short circuit and other fault settings. It can perform open circuit, short circuit, virtual connection, cross and wrong connection and other faults on the main lines of the control unit. The lower part is installed with an open-circuit simulation adjustable resistance, and the adjustable resistance is not less than 10K and 20K.

13. The port definitions of the control unit module end and the harness plug end are drawn on the detection panel. The drawing method of the module end and the plug end is the same as that of the original vehicle. Each port shall have at least 25 detection points, and the upper part shall be equipped with 12V red power detection terminal and GND black grounding terminal. The control unit includes engine computer ECM, hybrid control ECU, inverter low-voltage part, gateway, combination instrument, etc.

14. Supporting embedded new energy vehicle drive system teaching resource package software V1.0. The structure and control principle of Levin 1.8L dual-engine power drive are explained with 3D animation.

iii. Basic Configuration (Unit)

1 Detection control panel: 1 set

2 Combination meter: 1 set

3 Engine control computer (ECU): 1 set

4 Body computer (ECU): 1 set

5 Hybrid control computer (ECU): 1 set

6 Smart key computer (ECU): 1 set

7 Identification code box: 1 set

8 Air conditioning control computer (ECU): 1 set

9 Gateway (ECU): 1 set

10 Airbag computer (ECU): 1 set

11 Smart key receiver: 1 set

12 Smart key car antenna: 3

13 Diagnosis block OBDⅡ: 1

14 One-key start switch: 1

15 Smart key: 1

16 Shift lever seat: 1 set

17 Inverter assembly: 1

18 High voltage battery: 1 set

19 Battery blower assembly (with air duct): 1 set

20 High voltage cable: 1 set

21 P gear switch: 1 set

22 Electronic transmission axle: 1 set

23 Half shaft claw bearing: 1 set

24 Brake actuator: 1 set

25 Brake booster pump: 1 set

26 Brake pedal: 1 set (including brake travel sensor, brake switch)

27 Fuel pressure gauge 0-10kg/cm2: 1

28 Vacuum pressure gauge 0-76in.Hg: 1

29 Engine assembly 8ZR: 1 set

30 Carbon canister pump module: 1 set

31 Fuel tank: 1 (10L)

32 Gasoline pump (including gasoline pump plug): 1 set

33 Accelerator pedal: 1 set

34 Intake and exhaust pipes (with protective cover): 1 set

35 water tank (including stainless steel protective cover): 1 set

36 Cooling electronic fan: 1

37 battery: 1

38 relays: 1 set (including: starter relay, oil pump relay, cooling fan relay, etc.)

39 fuse box: 1 set

40 Main power switch: 1 (50A)

41 Intelligent fault setting and assessment system B-688: 1 set

42 Mobile platform (with self-locking caster device) 1800×1200×1000mm (length, width and height): 1 unit

43 Inverter electronic water pump: 1