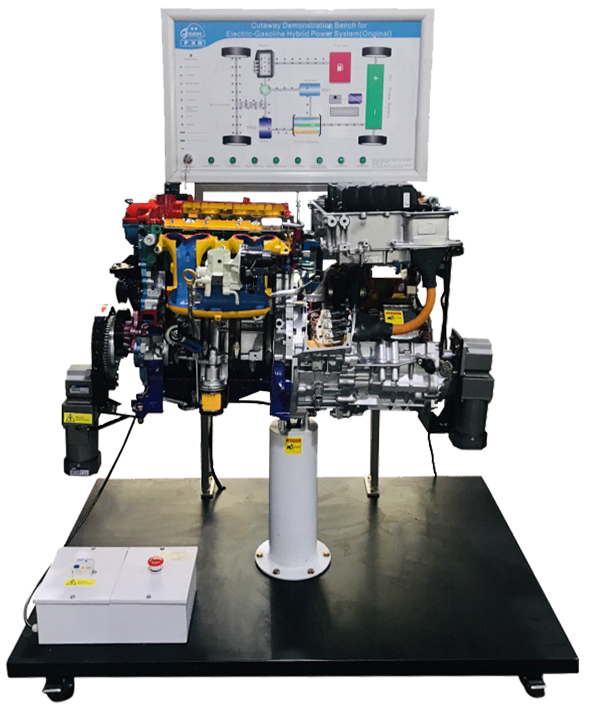

1. Complete and original hybrid power system from Toyota Corolla vehicle.

2. The engine, MG1, MG2 are drives by 220V electric motor to demonstrate the working process of main components in hybrid power system.

3. Front drive axle and front wheels and disc brakes are installed, these components can operate like the real vehicle.

4. A control panel is equipped to control the different working status of engine, motors and generator. And the panel can real-time show the energy flow direction between engine, motor, generator and battery and their working status at different driving status like real vehicle.

5. Four cylinders are installed with LED lights to simulate the working process of four strokes.

6. Cutaway are done on main components to check inside structure.

7. Check operation process of engine piston, valve, crank, hybrid transmission and others.

8. The surface of cutaway components are painted with different colors.

9. An electric leakage protection switch is installed for safety consideration.

10. An emergency stop switch is installed for safety consideration.

11. Lockable casters are installed to make it lockable and moveable.

12. Compliance with ISO and CE standards.

13. The language for this equipment is English or customized language.

14. The equipment is provided with operating manual, it contains the equipment introduction, hybrid power system components and working principle introduction, operation method. It’s helpful for promoting trainees troubleshooting skills.

1. Size: 1600mm x 1000mm x 1300mm (length x width x height)

2. Driving power supply: AC 220V±10%, 50/60Hz

3. Electric driving motors

4. Operating temperature: -40℃ to +50℃

Engine, Automatic transmission, MG1, MG2, Inverter, High voltage Power cable, Generator, Emergency switch, Power switch, Demonstration panel with control software, 8 different working conditions (By press the 8 buttons), Two 220V electric driving motors, Four LED lights in four cylinders, Front drive axle and front wheels and disc brakes, Movable framework with lockable casters.