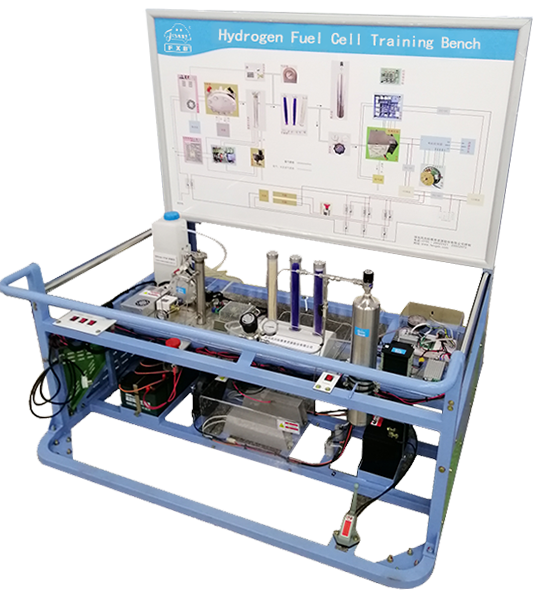

1. The whole hydrogen production system is placed on the bench according to the working state, and the whole process of hydrogen production, drying and hydrogen storage is fully displayed.

2. Under the condition of adding water to the tank in advance, the electrolyzer can start water electrolysis quickly. If the water tank is anhydrous, the electrolysis of water should be started 5 minutes after adding water to 2 / 3 of the water tank, the digital display screen is equipped to visually display the electrolysis rate of hydrogen (ml / min).

3. The oxygen produced by water electrolysis flows back from the oxygen water outlet of the electrolyzer to the water tank through the plastic air hose, and the oxygen is discharged into the atmosphere through the small hole on the cover of the water tank. The hydrogen produced by water electrolysis enters the hydrogen water separation device through the high-pressure air pipe from the hydrogen water outlet of the electrolyzer.

4. The hydrogen water separation device discharges most of the water carried in the hydrogen produced by electrolysis in the electrolytic cell to obtain relatively dry hydrogen.

5. The hydrogen from the hydrogen water separation device needs to be connected with a pressure gauge and an overpressure protector (pressure switch) to display the hydrogen pressure. When the hydrogen pressure is too high, the electrolysis power supply of the electrolytic cell is disconnected to stop the electrolysis.

6. The hydrogen through the hydrogen water separation device contains a small amount of water. After moisture absorption by desiccator, the purity of hydrogen can be over 99.99%.

7. The dried hydrogen enters the hydrogen storage bottle through the high-pressure air duct.

8. The high-pressure air pipe and various pipe joints used in the whole hydrogen pipeline can withstand the pressure of 2MPa.

9. The equipment has intelligent control function. When the water tank is short of water, the water shortage alarm will be triggered immediately.When there is water in the separator, the alarm will be triggered immediately and the electrolysis power supply will be automatically disconnected.

10. The training bench has a real and reliable mainstream hydrogen fuel cell vehicle power system, which can fully display the composition structure and control principle of the main parts.

11. The main components are installed on the bench and the electrical connection mode is the same as that of the power system of the hydrogen fuel cell vehicle, which can be easily disassembled. So that students can master the composition relationship of the power system of the hydrogen fuel cell vehicle in the process of assembly and disassembly.

12. The mainstream metal bipolar plate hydrogen fuel cell power supply system is selected for the training bench.The output working voltage is 21V (composed of 35 cells, each cell working voltage is 0.6V), the maximum power is not less than 200W, the overall dimension is not less than 130 * 95 * 110, and the performance is stable and reliable.

13. The original voltage of the hydrogen fuel cell power supply system directly supplies power to the intelligent electric drive system, and drives the intelligent electric drive system to work. The motor adopts the fully transparent external rotor permanent magnet synchronous motor, the motor speed can be adjusted, and the voltage display table is equipped to master the change of the original electric output parameters of the hydrogen fuel cell power supply system.

14. The training bench is equipped with FXB-AH booster controller to charge the 48V power battery pack after boosting to simulate the energy storage process of real vehicle. It is also equipped with 48V power battery pack discharge equipment, which can achieve real power consumption through two groups of aluminum shell resistance heating.

15.The training bench is equipped with FXB-AF step-down controller, 48V high voltage electricity is converted to 13.8V to supplement 12V lead-acid battery, which is used for power supply of vehicle low-voltage system.

16.The power supply system of hydrogen fuel cell and the output line of 48V power battery pack are respectively equipped with mechanical disconnect emergency switch, which is suitable for easily disconnecting the power supply circuit in case of emergency and ensuring the safety of the use process.

17. The training bench is equipped with aluminum alloy teaching board to draw the connection between the point circuit and the gas circuit of the hydrogen production system, as well as the working principle and circuit connection of the power system of the hydrogen fuel cell vehicle to show the connection control relationship between the various components.

18. The main control parts are connected with the safety detection port. With the help of DS2019-29 special digital clamp meter, the operation process of hydrogen fuel cell vehicle power system is measured, and the characteristics of voltage and current change are mastered.

19. Four wear-resistant casters are installed at the bottom of the training bench, which can move flexibly. At the same time, two casters at the front are equipped with self-locking devices, which can be fixed at any time.

1. Overall dimension of platform (mm): ≥700*700*1410 (L * W * H)

2. Overall dimension of teaching board (mm): ≥700*700 (L * W)

3. Working temperature of equipment: -5°~+35°

4. Electrolyzer Parameters:

Raw water: Ultra pure water (resistivity greater than 1m Ω · cm)

Electrode type: Pt / C Electrode

Electrolyte: Proton exchange membrane

Rated power: 90 W

Peak power: 100 W

Rated hydrogen generation rate: 300 Nml/min

Peak hydrogen production rate 300 Nml/min

Hydrogen production limit pressure: 1Mpa

Cooling mode: Natural air cooling, Water cooling (raw water)

5. Parameters of electrolytic power supply: AC220V-DC(5)V-(45)A

Input: 220V AC

Output current: (45)A,Constant current output

Maximum output voltage: (5)V

Short circuit protection: Yes

Overload protection: Yes

Heat dissipation mode: Fan cooling (temperature controlled)

Hydrogen fuel cell

6. Single cell specification 84*40

Nominal voltage (V): 21V

Maximum voltage (V): 35V

Nominal power (W): 200W

Minimum voltage (V): 19V

Maximum power (W): 250W

Weight (kg): 0.6

Rated current (A): 9.52

Maximum current (A): 13

Number of single cell: 35

Hydrogen pressure (Mpa): 0.06

Hydrogen purity: 99.99%

Overall dimension (mm): 96*111*120

7. Intelligent electric drive system:

All transparent external rotor permanent magnet synchronous motor, motor speed adjustable

8. FXB-AH Boost controller:

Input voltage range: 19V~35V

Output voltage range: 43.2V~55.2V

9. FXB-AF Step down controller:

Input voltage range: 19V~35V

Output voltage range: 10.8V~13.8V

10. 48V Power battery pack:

12V20AH Colloid maintenance free battery, 4 pieces in series, total capacity is 48V20AH

The cut-off voltage of discharge and charge is 43.2V and 55.2V respectively

11. Aluminum shell heating resistance: 2 pieces in total, each with power not less than 1KW

One set of water tank, one electrolytic power supply, one electrolytic cell (platinum electrode), one digital display board, one hydrogen water separation device, one control board (drainage board), one control power supply,one overpressure protector (pressure switch), one barometer, one set of dryer, plastic airway, metal airway, etc. One set of metal bipolar plate hydrogen fuel cell power supply system, one hydrogen storage tank, one set of intelligent electric drive system (including motor controller and motor),one FXB-AH boost controller, one FXB-AF step-down controller, one set of 48V power battery pack, two aluminum shell thermistors, two mechanical emergency power-off switches, one DS2019-29 automobile special clamp meter, one 12V45AH maintenance free battery, movable platform and teaching board.