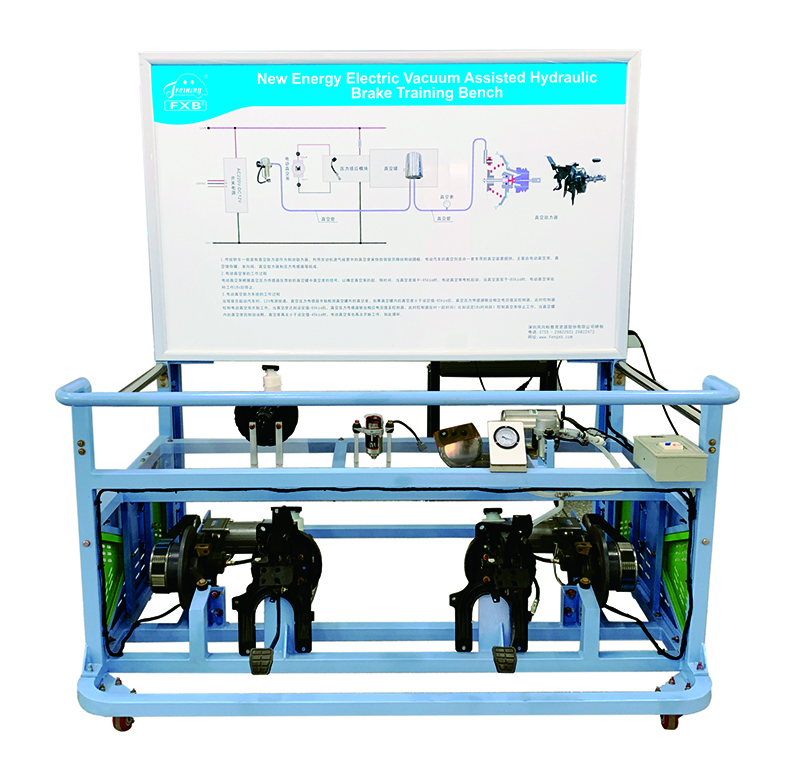

1. Real and operable new energy electric vacuum assisted hydraulic brake system fully demonstrates the structure and logic control relationship of the major components.

2. The main components are mounted on the bench, and the electrical connection is the same with the real car, which can be easily disassembled, so that trainees can grasp the key points of disassembly and assembly of hydraulic brake components in the process of disassembly and connection;

3. The vacuum gauge is connected with the vacuum tank, mounted on the panel, which also shows the vacuum pump current is closed and disconnected. Depress the brake pedal to observe the control relationship between the level of vacuum table and the vacuum pump running; when the degree of vacuum drops to -45Kpa, the pressure sensor makes the 12V power supply closed, and the vacuum pump will work; when the degree of vacuum is up to -80Kpa, the pressure sensor makes the 12V power supply disconnected, and the vacuum pump will stop working; (▲ FLASH logic control demo is provided on site, and the demonstration content matches the real bench, completely demonstrating the electric vacuum booster principle, including 2 kinds of states: vacuum pump works, and the vacuum pump stops working) Through the actual observation, the students master the pure electric vacuum booster working principle.

4. The training bench is placed horizontally, installed with the main components. It is installed with four lockable casters, it ensures that the training bench is moveable and can be fixed.

5. The training bench is equipped with brake guards and other security devices.

6. The training bench is equipped with the vacuum pump assembly, vacuum tank assembly and booster pump assembly, which are sectioned completely, clearly displaying the internal structure of the main components of electric vacuum booster system.

1. Dimensions (mm): 1000 * 1000 * 1800 (L * W * H)

2. Input Power: AC220V ± 10% 50Hz

3. Switching Power Supply: AC220V-DC12V-30A

4. Working temperature: -20 ° ~ + 40 °

Drive shaft, front wheel disc brakes, booster pump assembly, vacuum pump assembly, vacuum tank assembly, switching power supply, DC motor, vacuum gauge, mobile stand; vacuum pump assembly (sectioned), vacuum tank assembly (sectioned), Booster pump assembly (sectioned).