1. The device is equipped with pure electric car lithium iron phosphate battery pack, of which the nominal voltage is 72V and capacity is 50AH. It is built-in 23 series of lithium iron phosphate square batteries, with transparent design of power battery pack, to see clearly the internal components and connection ways.

2. The electric battery pack is equipped with 7-inch LCD display screen, synchronously displaying output current, and voltage actual value.

3. Scroll air-conditioning electric compressor is characterized with low noise, adjustable speed, range of 1500-3000rpm and rated speed of 2500rpm; condenser, evaporator, high and low pressure tubes, expansion valves and other refrigeration components are the same with the electric car ; It is also equipped with electric compressor speed regulator, which are mounted on the teaching board.

4. The device is equipped with high-pressure and low-pressure tubes pressure meters, to display the actual pressure changes in the working process of air-conditioning system.

5. The training bench is installed with 12V grounding mechanical switch. Disconnect the 12V grounding to cut off system power.

6. Equipped with 4mm aluminum-plastic panels, which makes a complete display of the working principle of air-conditioning system, and it is installed with detection terminals, to real-timely detect parameters under various states, with a multimeter.

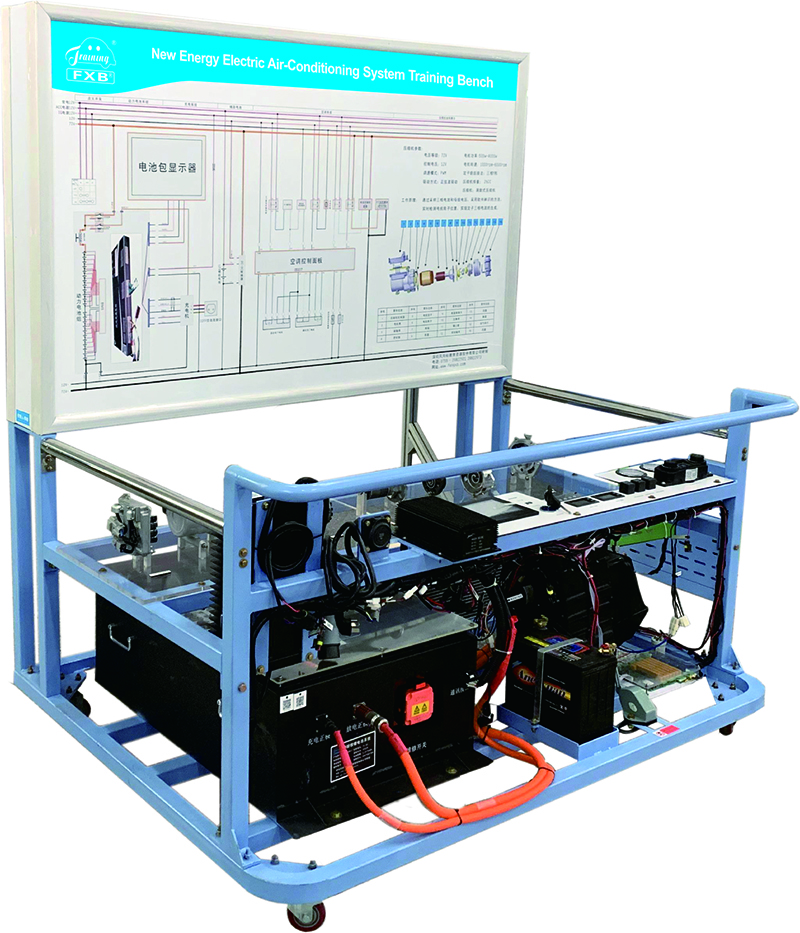

7. The training bench consists of a platform and a teaching board, and the platform is placed horizontally, installed with the main components. It is installed with four lockable casters, it ensures that the training bench is moveable and can be fixed.

8. Equipped with intelligent fault setting and assessment system, the teacher set the fault, the students analyze and find the fault, the main components is led to the test port , so the students can directly detect in the fault position, to master the troubleshooting abilities in real car.

1. Dimension (mm): 1600 * 1200 * 1800 (L * W * H)

2. Auxiliary battery: 12V45AH

3. Type of power battery: environmentally friendly lithium iron phosphate battery (square aluminum, single cell 3.2V50AH)

Capacity of power battery pack: 72V50AH (3.7 kWh) Times of fully charged and discharged: 2000 times

Working temperature: -20 ° ~ 60 °

4. Scroll air-conditioning electric compressor:

Displacement: 26ml / r Refrigerant: R134a

Refrigeration oil: RL68H 90ml Speed range: 1500-3000rpm

Rated speed: 2500rpm Operating noise: less than 65db

Voltage DC: 55-100V

Lithium iron phosphate battery pack, on-board charger, DC-DC converter, auxiliary battery, scroll air-conditioning electric compressor, condenser, expansion valve, evaporator, high and low pressure tubes, high pressure detection port and pressure gauge, low pressure test port and pressure gauge.