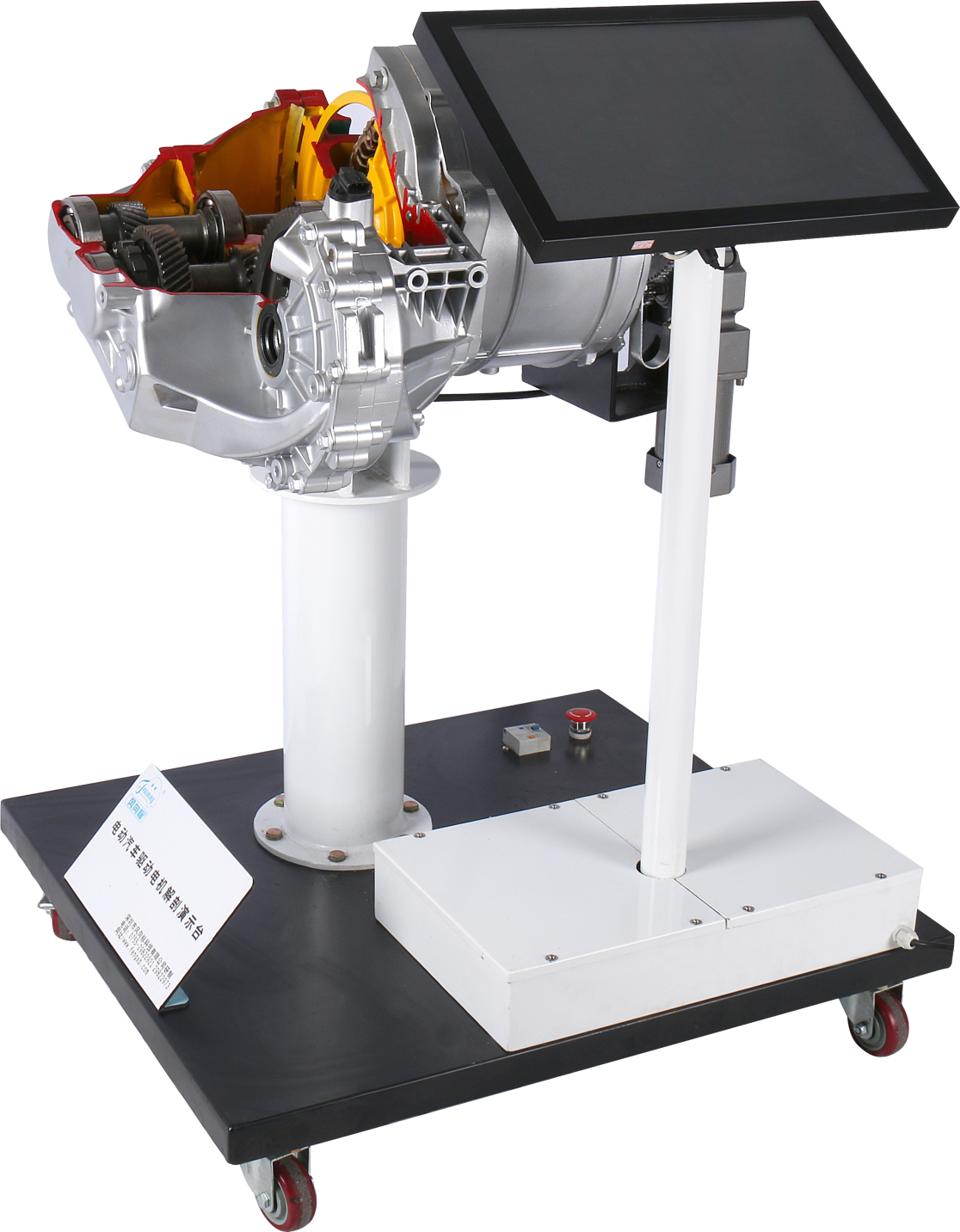

1) Permanent magnet synchronous motor is adopted for dissection, fully demonstrating the internal and external structure of the motor mechanism of electric vehicles, motor armature and rotor mechanism, winding modes of various motors and their working principles and processes.

2) Single-gear transmission is adopted for dissection, fully demonstrating the internal structure of electric vehicle transmission, and mastering the structural characteristics of pure electric vehicle transmission, which is only a two-stage helical gear transmission with only reduction function and no transmission function.

3) The mechanical sections are painted with different colors of paint.

4) It is equipped with a transparent protective cover. LED lighting is used in key parts, and protective devices such as insulating sheath are installed.

5) It is equipped with a large speed ratio stepless speed regulating motor, mounted on the spindle of the driving motor and controlled by a 19-inch integrated computer. The courseware is combined with software and hardware to simulate the energy distribution of the whole vehicle’s electric drive system under various working conditions. (▲ The function operation video of the dissection training platform for permanent magnet synchronous motor is provided on site. The structure and parts are clear, including the working state of the electric drive system and its energy distribution of the whole vehicle, including the starting, forward driving, reverse driving, deceleration, parking/idling and other working conditions of the power system, realizing the synchronization and coordination of software and hardware.)

6) The base of the training platform is welded with steel structure, and the surface is treated by spraying technology. With self-locking castor device, it is mobile, flexible, safe, reliable and durable.