Features

1. The main components are installed on the bench, the electrical connection mode is the same as that of the real vehicle, and can be easily removed after power failure, which enables the students to master the key points of disassembly and assembly of electric air conditioning and heating system parts in the process of disassembly and assembly of wiring.

2. The training bench is equipped with a high voltage DC power supply (AC220V to DC350V) to supply high voltage working power for the electric compressor and PTC heater.

3. The detection and maintenance of refrigeration performance are as following: the pressure detection and analysis of refrigeration system, temperature detection and analysis of refrigeration system, leakage detection and analysis of refrigeration system, control circuit detection of air conditioning compressor, disassembly and assembly of air conditioning control panel and circuit detection of air conditioning control panel.

4. The maintenance of refrigeration system components are as following: the disassembly and assembly of the electric compressor assembly, pipeline and electronic expansion valve, the disassembly and assembly of the evaporation box assembly, and the disassembly and assembly of the condenser and drying bottle.

5. The maintenance of heating system components includes the disassembly and inspection of PTC heater and electronic water pump.

6. The maintenance of ventilation system components includes the disassembly and assembly of the damper motor, the inspection of the damper circuit, the disassembly and assembly of the blower and module resistance, the disassembly and assembly of the air speed control panel, and the disassembly and assembly of the ventilation duct.

7. The detection of air-conditioning control circuit includes temperature sensor detection, sunlight sensor detection, automatic air conditioning control module detection, automatic air conditioning system fault code, data flow and action test.

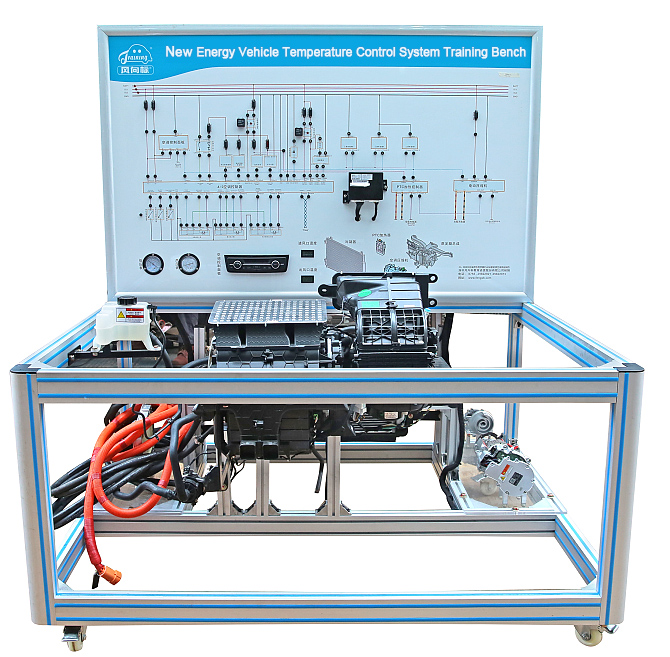

8. The teaching board completely displays the working principle diagram of the air conditioning and heating system. The detection terminals are installed with no less than 60 detection terminals. With the help of tools such as multi-meter and oscilloscope, the parameter changes in various states can be detected in real time. The width of the teaching board is not less than 1200mm, which can meet the needs of students to test and learn in different parts at the same time.

9. The training bench consists of a base frame and a teaching board. The base frame is placed horizontally and the main components are installed. Four lockable casters are installed on frame to make it stable and movable.

10. The training bench is also equipped with an air-conditioning compressor for disassembly and inspection.

11. The training bench is also equipped with a PTC heating module assembly for disassembly and inspection.

12. Equipped with an intelligent fault setting and assessment system, the teacher sets the fault, the students analyze and find the fault point, master the real vehicle fault handling ability of the students.

13. The training bench is also equipped with a clamp meter for automobiles and a high-voltage testing pen, which are used to control the measurement of line voltage, current and other parameters and the contactless measurement of large current in the orange high voltage circuit.

Product Parameters

1. Overall dimensions of aluminum alloy training bench (mm): not less than 1200*1200*1800 (length*width*height)

Dimensions of aluminum alloy teaching board (mm): not less than 1200*1000*200 (length*height*width)

2. Intelligent Power Supply:

Input Power: 220VAC

Maximum Input Power: 7KW, the external input line is two-phase three-wire system, safe grounding, the wire diameter is not less than 6 square meters, with leakage protection function.

Output Voltage: 0-350VDC

Output Current: 0-15A

The DC output terminal adopts the special high-voltage connector for new energy electric vehicles, with high-voltage interlock and anti-insertion error function.

Low Voltage Control Power Supply: DC12V

Basic Configuration

2 pieces of air-conditioning compressor (one of which is for disassembly), 1 piece of condenser, 1 piece of electronic expansion valve, 1 piece of evaporator, 1 piece of air conditioning panel, 1 piece of water pump assembly, 2 pieces of PTC heating module assembly (including 1 piece for disassembly), 1 piece of heater core assembly, 1 set of DC power supply (AC220V to DC350V15A), 1 piece of 12V29A switching power supply, 1 piece of automobile special clamp meter, 1 piece of high voltage testing pen, 1 set of movable bench and teaching board.