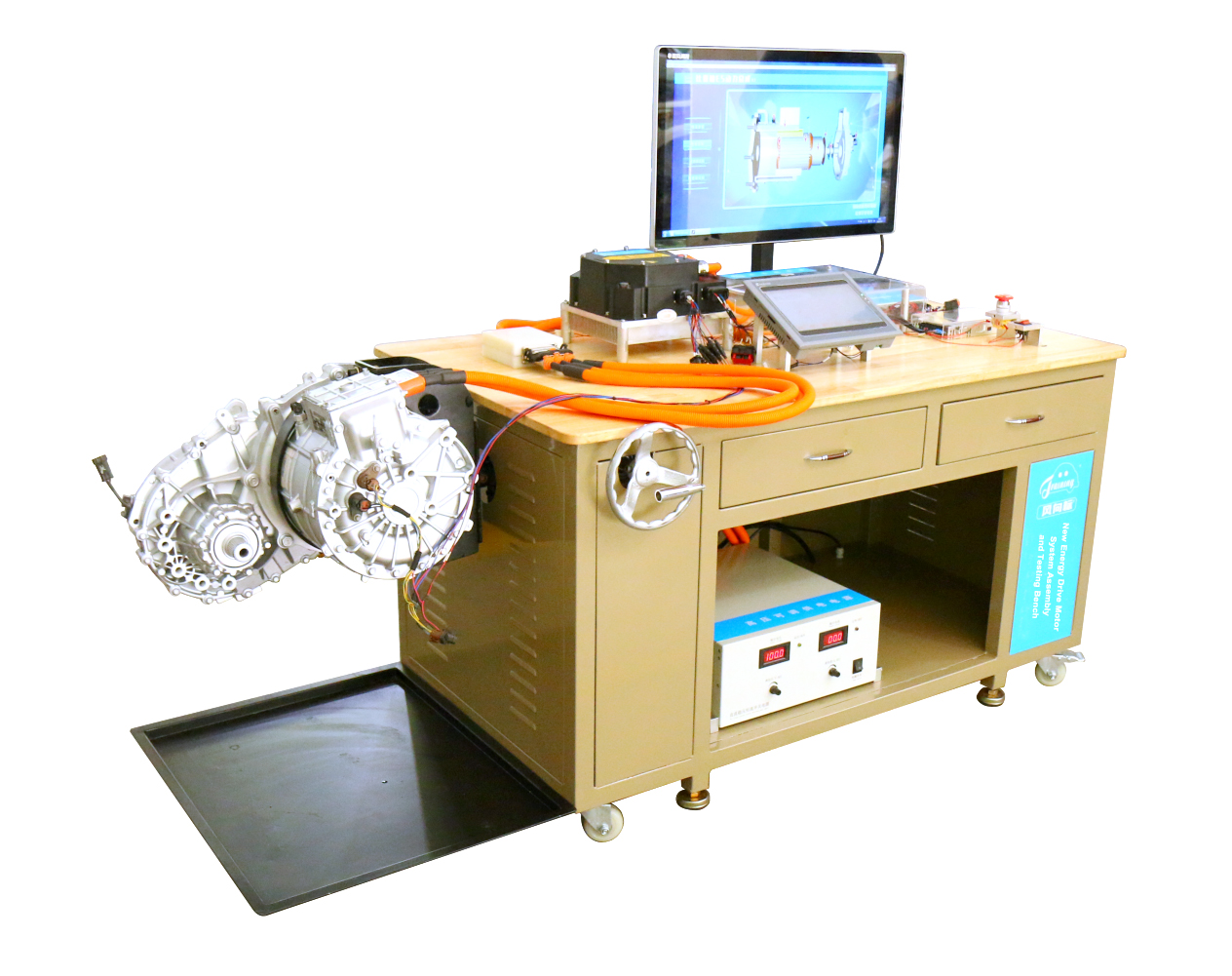

The training bench for the driving motor and control system of new energy vehicles is equipped with the motor controller and high-voltage distribution box of the whole vehicle, which can realize the operation state demonstration and conventional signal detection of permanent magnet synchronous motor. And It can carry out the disassembly and mechanical maintenance of gearbox components, idling inspection of driving motor, cold insulation resistance detection, winding short circuit inspection, winding open circuit inspection, winding resistance inspection of rotary transformer sensor, resistance inspection of motor winding temperature sensor and other training items.The equipment is mainly composed of powertrain training platform, motor control system, upper computer intelligent information acquisition and detection system, driving energy supply platform, three-phase high-voltage connecting cable, low-voltage communication connecting cable and other important components. Equipped with a drive system resource package, the device applies to the test and detection of the driving motor of the electric drive system of new energy vehicles, teaching training, practical training assessment and skill appraisal.

II. Function:

1.The motor type is mainstream electric vehicles commonly used three-phase permanent magnet AC synchronous motor. When the motor operates normally, the phase of three-phase electricity and the signal of rotary transformer sensor can be measured with the help of oscilloscope.

2.Equipped with convenient separation of motor and gearbox and 360° arbitrary turnover mechanism of gearbox, it makes the disassembly and assembly of power assembly convenient and fast.

3.The plug of the input and output of the motor low voltage control signal adopts the low-voltage signal plug of the original new energy vehicle, which fits the teaching of real vehicle parts to the greatest extent.

4.The voltage signal detection between stator windings can be completed with the help of multimeter.

5.Equipped with motor three-phase voltage signal and motor resolver signal detection point, so it is convenient to diagnose and analyze the signal waveform with the help of oscilloscope and other equipment.

6.The equipment adopts high-voltage power supply with input voltage of AC220V ± 10% and output voltage stabilizing value of not less than 72V DC. It has the functions of input overload and open circuit protection, output overvoltage protection, output overcurrent protection and output short circuit protection. At the same time, the VCU vehicle controller detects the voltage and current to ensure the safety of the system.

7.The bench is equipped with a motor wire interface, a motor resolver sensor interface and a ground wire interface, which can be easily connected to an intelligent motor controller to supply power to the motor.

8.The VCU vehicle controller controls the power on process and has the functions of precharge voltage detection and high voltage interlock detection, which can detect the voltage at both ends of the precharge resistance in real time. Through the touch screen, the control of power on / power off of the system, power on / power off of the controller, start / stop of the controller, forward / reverse rotation of permanent magnet synchronous motor, acceleration / deceleration of permanent magnet synchronous motor can be realized, and the working states such as input voltage, current and relay pull-in can be monitored in real time.

9.The mainstream pure electric permanent magnet synchronous motor and controller are connected to both ends of the high-voltage cable respectively. One end is fixed with the U/V/W high voltage interface of the permanent magnet synchronous motor, and the connection plug is the same as the original car. The other end is connected with the motor controller, and a high-voltage quick connect plug is added in the middle, which is equipped with high-voltage interlock. Disconnect the high-voltage interlock connecting circuit and cut off the power of the whole system, which is convenient for the control and teaching of high-voltage interlock circuit.

10.The detection panel is made of acrylic material, Its surface are processed by special craft and spraying primer. The detection terminal with protection function is installed, and the name of the detection terminal is silk screen printed in white font.

11.The equipment is supporting with new energy vehicle drive system teaching resource package software V10. And the structural composition and control principle of the drive motor assembly of mainstream new energy vehicles are explained in the form of three-dimensional animation.

12.It is equipped with one digital insulation tester for new energy vehicle competition and one special clamp gauge for vehicle, which is used for line voltage, current and other parameter measurement and large current non-contact measurement of orange high-voltage circuit.