The original BYD e5 A/C and heating system is selected. It truly presents the connection and control relationship, installation location and operation parameters between the core parts of the BYD e5 A/C and heating system, and trains the trainees’ ability to analyze and deal with the faults of the BYD e5 A/C and heating system. It is suitable for the new energy pure electric course teaching and maintenance training in vocational and technical colleges.

The working principle mainly includes two systems: A/C refrigeration and warm air heating:

1. A/C cooling system:

An electric compressor driven by an air-conditioner driver pulls the gaseous refrigerant out of the evaporator and pushes it into the condenser. When the high-pressure gaseous refrigerant is liquefied through the condenser, it carries out heat exchange (releasing heat), and the heat is taken away by the air outside the vehicle. The high-pressure liquid refrigerant is depressurized by the throttle action of the expansion valve, and the low-pressure liquid refrigerant is vaporized in the evaporator for heat exchange (heat absorption). The cooled air near the evaporator is blown into the carriage by a blower. The gaseous refrigerant is removed by the compressor and pumped into the condenser. In this way, the refrigerant flows in a closed cycle, continuously discharging the heat from the inside of the vehicle to the outside of the vehicle, and lowering the temperature inside the vehicle to a suitable temperature.

2. Warm air heating system

PTC water heater assembly is used to heat the coolant in the heating system. The coolant is first pumped into the PTC water heater assembly by the pump from the A/C heating sub-tank assembly. The heated coolant flows through the warm air core and then returns to the A/C heating sub-tank assembly, and so on.

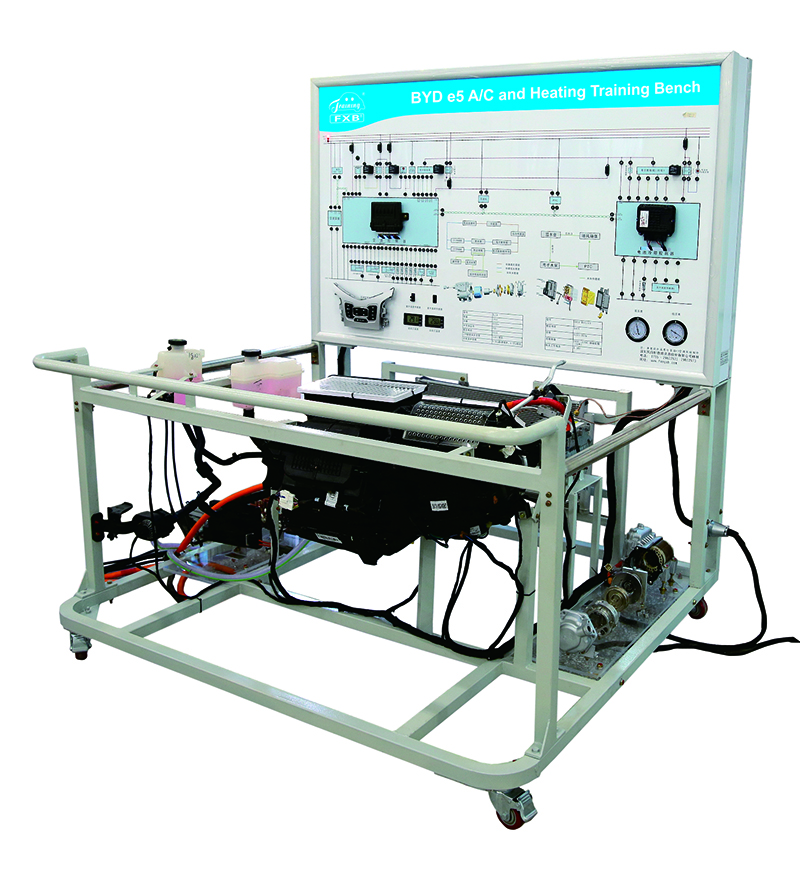

1.The main components are installed on the platform, and the electrical connection is the same as that of the real vehicle. It is convenient to disassemble after powering off, so that students can master the key points of disassembly and assembly of electric A/C and heating system parts in the disassembly and assembly connection process.

2.With the help of intelligent switch, the logic relationship under different working conditions of A/C and heating can be reproduced on the display screen of intelligent mobile platform (FLASH logic control demonstration can be provided on site).

3.The training platform is connected to the training platform of the power battery and management system. The connecting cable is the same as that of the original vehicle. The training platform is powered by the power battery and management system.

4.With the help of the supporting courseware data, the functions of main parts and pin definitions are fully described on the display screen of intelligent mobile platform.

5.The teaching board fully displays the working principle diagram of the A/C and heating system, and is equipped with detection terminals. With the help of a multimeter and oscilloscope, the parameter changes in various states can be detected in real time.

6.The training platform consists of a platform and a teaching board. The platform is placed horizontally and installed with main parts. Four casters are installed at the bottom of the training platform, which can move flexibly. Meanwhile, casters are equipped with self-locking device, which can fix the position.

7.The training platform is also equipped with an A/C compressor, which is displayed in an explosive way to clearly understand the internal structure and working mode of the electric A/C compressor of the refrigeration system. The teaching board is used to draw the working principle of the electric A/C refrigeration system.

8.The training platform is equipped with another PTC heating module assembly, which is displayed by explosion mode to clearly understand the internal structure and working mode of PTC heating module assembly of the heating system. The teaching board draws the intelligent control method of the heating system.

9.It is equipped with intelligent fault setting and assessment system. The teacher sets the fault, and the student analyzes and finds the fault point. The main parts are drawn out of the test port and directly tested at the fault location to grasp the real vehicle fault handling capacity.

10.The practical training platform is equipped with the practical training instruction, which fully describes the working principle of the practical training platform, training subjects, fault setting and elimination, and other key points.

2 A/C compressors (one of which is displayed in dissection), 1 condenser, 1 electronic expansion valve, 1 evaporator, and 1 A/C panel; 1 water pump assembly, 2 PTC heating module assemblies (one of which is displayed in dissection), 1 heating core assembly, and 1 set of mobile platform and teaching board.