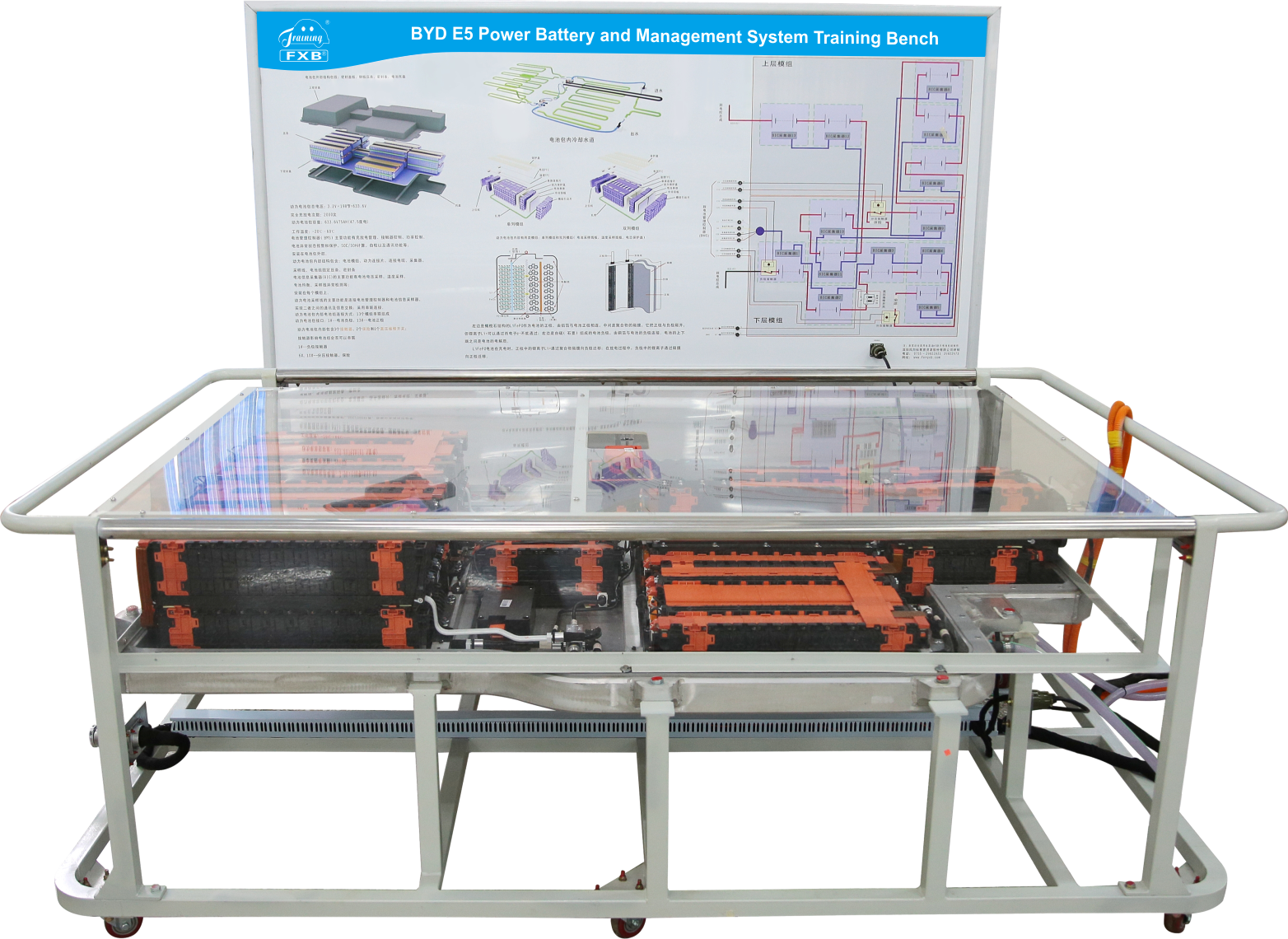

1.The main components are installed on the platform, and the modification is transparent without changing the original vehicle's layout, which is conducive to understanding the battery structure, and it is strictly prohibited to contact to ensure safe learning. Both the low-voltage control line and the high-voltage power line are original vehicle parts, and the length is increased. The high-voltage power line is orange, with an additional protective bellows, and a warning sign is added at the joint. It is forbidden to plug and unplug any high-voltage power line under the condition of power on. It enables students to understand the components and connections of power batteries as soon as possible.

2.The distributed battery management system consists of 1 battery management controller (BMC), multiple battery information controllers (BICs) and 1 set of power battery sampling line. The main functions of the battery management controller are charge and discharge management, contactor control, power control, abnormal battery status alarm and protection, SOC/SOH calculation, self-inspection and communication functions, etc. The main functions of the battery information collector are battery voltage sampling, temperature sampling, battery balance, abnormal detection of the sampling line, etc. The main function of power battery sampling line is to connect battery management controller and battery information collector to realize communication and information exchange.

3.BMS battery management system has the function of passive balance, six-way switch control protection (mono-disconnection, short circuit, overvoltage, undervoltage, overcurrent, and overtemperature), communication with CAN of the charger, control of vehicle charger work through BMS, SOC (state of charge) estimation, etc.

4.BYD e5 intelligent data acquisition system can be added. Through bluetooth wireless transmission, with the help of intelligent mobile platform or computer display, various parameters in the charging and discharging process can be observed, and the control logic and variation rules of main component parameters in the charging and discharging process of power battery pack can be mastered.

5.With the help of intelligent switch, the control logic in various states can be reproduced on the intelligent mobile platform. The content of the demonstration is consistent with the real object.

6.The training platform provides power source for high-voltage control system and other training platforms. The high-voltage power line and the low-voltage control line are the original vehicle parts, and the connection mode is the same as the original vehicle.

7.With the help of the supporting courseware data, the functions and pin definitions of the main components, including the five lines of communication between the power battery pack and the BMS, are fully described on the display screen of the intelligent mobile platform.

8.The training platform is equipped with teaching board, which can fully display the working principle diagram of power battery pack, charging and discharging. The low-voltage control circuit is equipped with detection terminals. With the help of multimeter and oscillograph, parameter changes in various states can be detected in real time.

9.The training platform consists of a platform and a teaching board. The platform is placed horizontally and installed with main parts. Four casters, two universal wheels and two directional wheels are installed at the bottom of the platform, which can move flexibly. Meanwhile, universal casters are equipped with self-locking device, which can fix the position. Casters have low rolling resistance and wear resistance. The teaching board is installed separately, four casters are also installed, which can be moved separately.

10.It is equipped with intelligent fault setting and assessment system. The teacher sets the fault, and the student analyzes and finds the fault point. The fault point is mainly set in the low-voltage control line, i.e., to ensure the safety of the high-voltage system, and to grasp the real vehicle fault handling capacity at the same time.

11.The practical training platform is equipped with the practical training instruction, which fully describes the working principle of the practical training platform, training subjects, fault setting and elimination, and other key points.

1.Overall dimensions (mm) of the frame: Not greater than 2400*1450*860 (length*width*height)

Dimensions (mm) of the teaching board: Not greater than 2400*1200*200 (length*height*thickness)

Dimensions (mm) of the teaching board base: Not greater than 2400*700*750 (length*width*height)

2.High-voltage power bus power supply: DC 604.8V

3.Low-voltage control operating power supply: DC 12V

4.Type of power battery: Nickel-cobalt-manganese ternary lithium power battery

Single cell: 3.6V 100AH

Total voltage of power battery pack: 3.6*168=604.8V

Power battery pack capacity: 604.8V 100AH (about 60 kWh)

Total charge and discharge times: 2,000 times

Operating temperature: -20°~60°

5.Battery management system (BMS) The distributed battery management system consists of 1 battery management controller (BMC), 6 battery information controllers (BICs) and 1 set of power battery sampling line.

A lithium iron phosphate power battery pack (including 13 power battery modules), 6 distributed battery management system collectors, 1 set of orange high-voltage power line, 1 set of low-voltage control line, 1 repair switch control box, 1 movable platform and 1 movable teaching board.