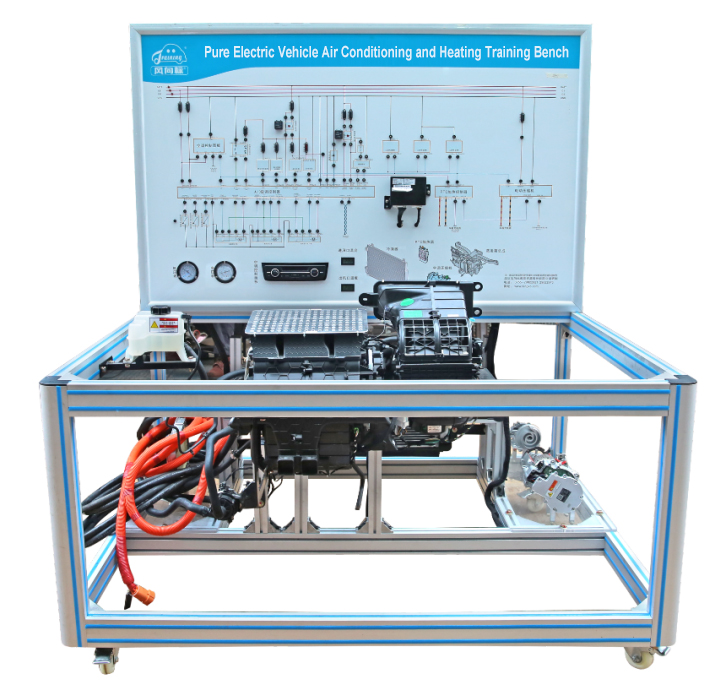

The mainstream pure electric vehicle BYD Qin EV air conditioning and heating system are selected. The training bench can be used for heating, cooling, blowing mode conversion and practical operation of internal and external air circulation. The 220V AC power is converted to 350V DC through the grid input, providing high-voltage DC output for the electric compressor and PTC heater. The training bench can truly demonstrate the composition and working process of the electric air-conditioning system. Equipped with electric air-conditioning system circuit diagram, the product applies to the teaching needs of electric air-conditioning system inspection and maintenance training of secondary and senior vocational schools, ordinary education and training institutions.

II. Features

1. The main components are installed on the bench, and the electrical connection method is the same as that of the real car. It can be easily disassembled after power failure, so that students can master the disassembly and assembly points of the electric air conditioner and heating system parts during the process of disassembly and assembly.

2. The training bench is equipped with a high-voltage DC power supply (AC220V to DC350V) to supply high-voltage working power for the electric compressor and PTC heater.

3. The detection and maintenance of refrigeration performance includes the pressure detection and analysis of refrigeration system, the temperature detection and analysis of refrigeration system, the leakage detection and analysis of refrigeration system, the control circuit detection of air conditioning compressor, the disassembly and assembly of air conditioning control panel and the circuit detection of air conditioning control panel.

4. The maintenance of refrigeration system components includes disassembly and assembly of electric compressor assembly, pipeline and electronic expansion valve, disassembly and assembly of evaporation box assembly, disassembly and assembly of condenser and drying bottle.

5. The maintenance of heating system components includes the disassembly and assembly and inspection of PTC heater and electronic water pump.

6. The maintenance of ventilation system components includes the disassembly and assembly of damper motor, the detection of damper circuit, the disassembly and assembly and detection of blower and module resistance, the disassembly and assembly of wind speed control panel and ventilation duct.

7. The detection of air conditioning control circuit includes the detection of temperature sensor, sunlight sensor, automatic air conditioning control module, automatic air conditioning system fault code, data flow and action test.

8. The teaching board completely displays the working principle diagram of the air conditioning and heating system, and installs detection terminals, with 60 detection terminals. With the help of tools such as a multimeter and an oscilloscope, the parameter changes in various states can be detected in real time. And the width of the teaching board is 1200mm, which can meet the students test and learn in different parts.

9. The equipment is composed of a bench and a teaching board, The bench is placed horizontally and the main components are installed. 4 lockable casters are installed to ensure that the bench is flexible.

10. The training bench is also equipped with an air-conditioning compressor for disassembly and assembly and inspection.

11. The training bench is also equipped with a PTC heating module assembly for disassembly and assembly and inspection.

12. Equipped with intelligent fault setting and appraisal system.

13. The training bench is also equipped with a special clamp meter and a high-voltage test pen for the new energy vehicle competition, which are used to control the line voltage, current and other parameters measurement and the orange high-voltage loop high-current non-contact measurement.

14. The equipment is provided with the original car circuit diagram and complete training instructions for the equipment.

15. The teaching resource package software V1.0 of the new energy vehicle temperature control system can be extra equipped(Optional). The structure and control principle of the mainstream new energy vehicle temperature control system are explained with 3D animation.

III.Technical Parameter

1. Dimensions of aluminum alloy bench (mm): 1200*1000*1800 (length*width*height)

Dimensions of aluminum alloy teaching board (mm): 1200*1000*200 (length*height*thickness)

2. Intelligent power source: input power: 220VAC, maximum input power: 7KW, external input line is two-phase three-wire system, safe grounding, wire diameter 6 square meters, with leakage protection function, output voltage: 0-370VDC (adjustable), Output current: 0-15A, the DC output end uses high-voltage connectors dedicated to new energy electric vehicles, with high-voltage interlocking and anti-insertion functions.

3. Low-voltage control working power supply: DC12V

IV. Basic Configuration

1. Detection control panel: 1 set (With various detection terminals and color diagram)

2. Aluminum alloy stand: 1 set { 1200*1200*1800 (length*width*height)}

3. Air conditioning control panel: 1

4. Electric compressor (including a set of compressor controller): plus 1 set of split display pieces.

5. Air conditioner high pressure gauge: 1

6. Air conditioner low pressure gauge: 1

7. Thermometer: 2

8. Electronic fan: 2

9. Air conditioner pressure switch: 1

10. PTC heater: 2

11. Air conditioner condenser: 1

12. Air conditioner evaporator: 1

13. Air conditioner blower: 1 set

14. FXB vehicle CAN simulation board: 1 set

15. High voltage DC stabilized power supply: 1 (DY-350V 15A)

16. A/C controller: 1

17. Heating water pump: 1

18.12V switching power supply: 2 (12V 29A)

19. Intelligent fault setting system: 1 set

20. Cooling water tank: 1

21. Leakage protection switch: 1 (220V 32A)