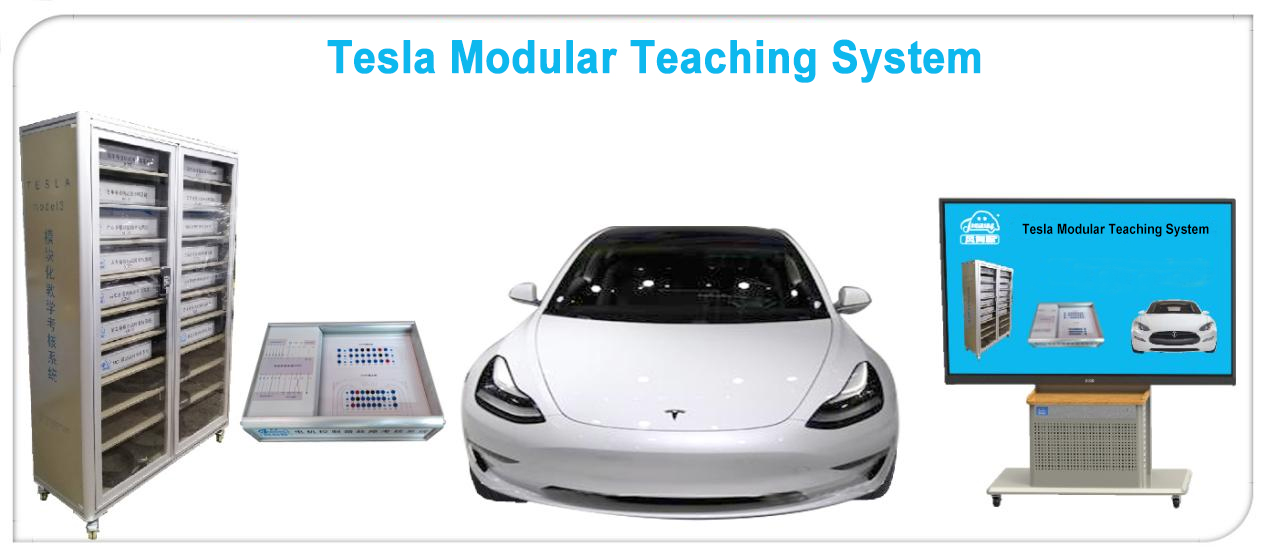

This device is used with the normal operable Tesla model 3 pure electric car. On the basis of not damaging the main harness of the original vehicle, the whole vehicle will be transformed into an online fault detection teaching car, which can detect and diagnose the dynamic and static signal parameters of the original vehicle motor control system, high-voltage battery system, left front body module, right front body module and charging module in real time. The main circuit of the main control unit can be set for open circuit, virtual connection, short circuit , and the fault setting method is reliable. It is equipped with a portable IOT placement cabinet, which can manage the equipment, allocate the use authority and supervise the use status of tools through the Internet of things. And it has Tesla high-voltage battery system and drive motor system resource package, which is convenient for teaching. The device applies to the teaching needs of pure electric vehicle theory and maintenance training of secondary and senior vocational schools, ordinary education and training institutions.

II. Function

1.It is connected with the whole vehicle through the main harness, and the integrity of all functions of the original vehicle can be maintained after disconnecting the main harness.

2.It can display the dynamic and static signal parameters of the whole vehicle through the display of the original vehicle (such as: energy monitor screen, vehicle speed, gear position display and indicator lights of various working conditions, etc.).

3.Through the main integrated modular detection and fault setting box, it is connected in series with the original vehicle harness to lead the control signal to the modular detection and fault setting box for detection and fault setting. The outgoing interfaces are the main control modules of the original vehicle, including the original vehicle motor control system, high-voltage battery system, left front body module, right front body module and charging module. After detecting the fault setting, the control signal will be connected back to the original vehicle control unit, and the total number of fault points is not less than 200. Some of the plugs are the same as the original vehicle wiring harness. The connecting line adopts the national standard Teflon automobile special wire, and the withstand voltage is not less than 600V to ensure that the circuit signal of the whole vehicle is normal. At the same time, the signal is led from the central console to the modular detection and fault setting box. The main module terminals and plug terminals of the original vehicle are drawn on the upper part of the measurement box, which can directly measure the real-time signal of the whole vehicle on the terminal and master the variation law of parameters of different control units. The bottom of the measuring box adopts push-pull design, and a fault setting system is installed inside, which can carry out short circuit, open circuit, virtual connection and other faults on any line of the control unit.

4. The front body control module is led out to the teaching board, which can detect the voltage signal or network signal of battery cooling water pump, driven cooling water pump, pressure temperature sensor, compressor, temperature sensor, 8-way valve, etc.

5.The left front body control module is led out to the teaching board, which can detect the left rear outer door handle switch, left rear door lock, rear window switch, rear window motor, seat adjustment, seat heating, left electric rearview mirror, left front door lock, left front outer door handle, left front door inner handle, left front window motor and other signals.

6.The right front body control module is led out to the teaching board, which can detect the upper air outlet motor of the air conditioner, the lower air outlet motor, the left air outlet motor, the air inlet motor, the right air outlet motor, the footwell air outlet sensor, and the evaporate temperature sensor. Ultrasonic sensor, right vane mode switch, left vane mode switch, cab temperature sensor, right rear window motor, right parking motor, rear inner taillights and other signals.

7.The motor controller system is led out to the teaching board, which can detect signals including accelerator pedal, motor inverter, CAN network, high voltage interlock, power supply and so on.

8.The charging module system is led out to the teaching board, which can detect signals including CAN network, CC signal, temperature detection, high voltage interlock, charging indicator light, power supply and so on.

9.The high-voltage battery system is led out to the teaching board, which can detect signals including CAN network, CP signal, high-voltage interlock, power supply, etc.

10.The detection panel is made of 4mm-thick advanced aluminum-plastic plate with characteristics of corrosion resistance, impact resistance, pollution resistance, fireproof, and moistureproof. Its surface are processed by special craft and spraying primer. The panel is printed with never fade color control unit, actuator and sensor terminal diagram, and the detection terminals are installed. And students can intuitively compare the circuit diagram and the original car to measure and analyze the working principle and signal transmission process of each control system.

11.The fault setting measurement box adopts all aluminum frame structure, lightweight design, and sliding-cover fault setting and detection area, which is convenient to use.

12.The movable cabinet door of the module placement cabinet, with translucent design, which can place modules and wire harnesses inside. The placement cabinet integrates the IOT function, which can use the Honor tablet to uniformly manage the equipment, assign the use authority and query the use record.

13.It adopts the original six pin three gear mechanical fault setting mode imported from Japan, and is equipped with high-precision adjustable resistance to set the short circuit fault of the main harness.

14.According to customer needs, the resource package courseware of Tesla's high-voltage battery system and drive system, and a 72-inch all-in-one display stand can be optional added.(This is determined by the customer needs, the standard product does not equip.)

15.The equipment is equipped with electronic circuit diagram, and the instruction manual for fault setting and troubleshooting.